|

시장보고서

상품코드

1716618

레이저 용접기 시장 기회, 성장 촉진요인, 산업 동향 분석, 예측(2025-2034년)Laser Welding Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

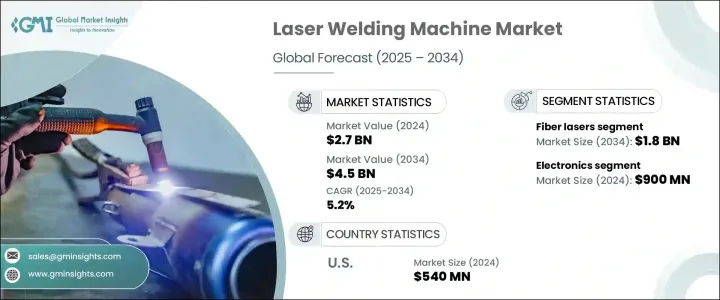

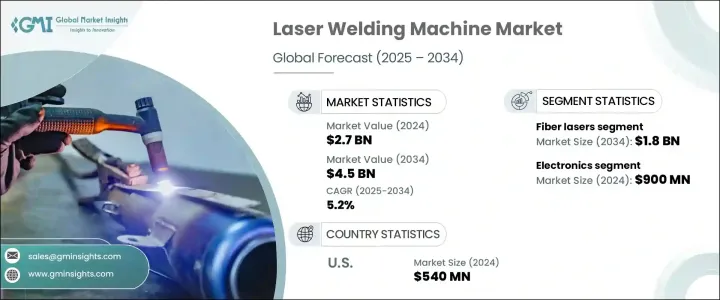

레이저 용접기 세계 시장은 2024년에 27억 달러에 달했으며, 2025년부터 2034년까지 5.2%의 CAGR로 성장할 것으로 예상됩니다.

자동차, 항공우주, 전자, 의료기기 등의 산업에서 첨단 용접 솔루션을 지속적으로 채택함에 따라 고정밀 제조 공정에 대한 수요가 증가함에 따라 이 시장의 급격한 성장을 주도하고 있습니다. 레이저 용접 기술은 타의 추종을 불허하는 정확성, 속도, 재료의 무결성을 손상시키지 않고 내구성 있는 용접부를 형성할 수 있는 능력으로 인해 현대 제조업에 없어서는 안 될 필수 요소로 자리매김하고 있습니다. 전기자동차와 자율주행차 생산이 급증함에 따라 정밀도와 효율성을 제공하는 첨단 용접 시스템에 대한 요구가 그 어느 때보다 높아지고 있습니다.

기업들이 생산능력 향상과 가동 중단 시간 단축에 주력하는 가운데, 레이저 용접기는 원활한 고품질 제조를 가능하게 하는 중요한 구성요소로 부상하고 있습니다. 또한, 전자제품과 의료기기를 중심으로 다양한 산업에서 소형화 추세가 강화되면서 기존 방식으로는 차세대 제품의 정밀도를 충족할 수 없는 경우가 많기 때문에 비접촉식 용접 솔루션의 채택이 제조업체를 이끌고 있습니다. 인더스트리 4.0의 발전과 함께 자동화 혁신은 공정 간소화와 생산성 향상을 위해 레이저 용접기를 도입하는 제조업체의 노력을 더욱 가속화시키고 있습니다. 제조 작업에서 지속가능성과 에너지 효율성에 대한 관심이 높아지면서 폐기물을 줄이고, 재료 사용을 최적화하며, 일관된 결과를 얻을 수 있는 레이저 용접 기술로의 전환을 촉진하는 주요 요인으로 작용하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 27억 달러 |

| 예상 금액 | 45억 달러 |

| CAGR | 5.2% |

레이저 용접 기술은 우수한 정확성, 효율성, 적응성으로 인해 기존 용접 방법보다 널리 선호되고 있습니다. 시장은 레이저 기술별로 세분화되어 파이버 레이저, CO2 레이저, 다이오드 레이저 및 기타가 주요 제품 유형으로 분류됩니다. 이 중 파이버 레이저가 압도적인 점유율을 차지하고 있으며, 2024년에는 12억 달러로 평가되며 2034년까지 18억 달러에 달할 것으로 예상됩니다. 파이버 레이저는 뛰어난 빔 품질, 에너지 효율, 운영 비용 절감으로 업계에서 높은 지지를 받고 있습니다. 이러한 레이저는 왜곡 없이 복잡하고 섬세한 부품을 용접할 수 있기 때문에 자동차, 의료기기 제조, 전자제품 등 정밀도가 가장 중요한 분야에서 필수적인 역할을 하고 있습니다.

또한 시장은 자동차, 의료, 전자, 전자, 항공우주, 보석과 같은 최종 사용 산업을 기준으로 세분화되어 있습니다. 전자 부문은 2024년 9억 달러로 평가되며, 반도체, 회로 기판, 마이크로일렉트로닉스와 같은 소형 및 복잡한 부품의 정밀 용접 수요로 인해 예측 기간 동안 CAGR 3.8%로 성장할 것으로 예상됩니다.

미국의 레이저 용접기 시장은 2024년 5억 4,000만 달러 규모에 달했으며, 자동화, 전기자동차 제조, 반도체 제조의 발전에 힘입어 2025년부터 2034년까지 연평균 5.3%의 성장률을 기록할 것으로 예상되며, 미국은 파이버 레이저 기술의 주요 거점이 될 것입니다.

목차

제1장 조사 방법과 조사 범위

제2장 주요 요약

제3장 업계 인사이트

- 업계 생태계 분석

- 밸류체인에 영향을 미치는 요인

- 이익률 분석

- 디스럽션

- 향후 전망

- 제조업체

- 유통업체

- 소매업체

- 영향요인

- 성장 촉진요인

- 자동차 산업 확대

- 제조 활동 급증

- 레이저 용접 기술 진보

- 업계의 잠재적 리스크·과제

- 높은 초기 투자와 유지보수 비용

- 조작과 프로그래밍에 숙련된 노동력이 한정

- 성장 촉진요인

- 기술 혁신 상황

- 성장 가능성 분석

- 규제 상황

- 가격 분석

- Porters 분석

- PESTEL 분석

제4장 경쟁 구도

- 소개

- 기업 시장 점유율 분석

- 경쟁 포지셔닝 매트릭스

- 전략 전망 매트릭스

제5장 시장 추정과 예측 : 기술별, 2021-2034년

- 주요 동향

- 파이버 레이저

- CO2 레이저

- 다이오드 레이저

- 기타

제6장 시장 추정과 예측 : 최종 용도별, 2021-2034년

- 주요 동향

- 자동차

- 의료

- 일렉트로닉스

- 항공우주 및 방위

- 주얼리

- 기타

제7장 시장 추정과 예측 : 유통 채널별, 2021-2034년

- 주요 동향

- 직접

- 간접 판매

제8장 시장 추정과 예측 : 지역별, 2021-2034년

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 이탈리아

- 스페인

- 러시아

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주

- 라틴아메리카

- 브라질

- 멕시코

- 중동 및 아프리카

- 사우디아라비아

- UAE

- 남아프리카공화국

제9장 기업 개요

- CHIRON Group

- Coherent

- Emerson Electric

- Han's Laser Technology Industry Group

- Huagong Laser Engineering

- IPG Photonics

- Jenoptik

- KEYENCE

- Laser Technologies

- Laser line

- Laser Star Technologies

- Penta Laser

- Precitec

- TRUMPF

The Global Laser Welding Machine Market reached USD 2.7 billion in 2024 and is projected to grow at a CAGR of 5.2% between 2025 and 2034. The rising demand for high-precision manufacturing processes is driving the rapid expansion of this market, as industries such as automotive, aerospace, electronics, and medical devices continue to adopt advanced welding solutions. Laser welding technology has become an essential part of modern manufacturing for its unmatched accuracy, speed, and ability to create durable welds without compromising material integrity. With the surge in electric and autonomous vehicle production, the need for advanced welding systems that offer precision and efficiency is stronger than ever.

As companies focus on improving production capabilities and reducing downtime, laser welding machines are emerging as a critical component in enabling seamless, high-quality manufacturing. Moreover, the growing trend of miniaturization across various industries, especially electronics and medical devices, is pushing manufacturers to adopt non-contact welding solutions, as traditional methods often fall short of meeting the precision demands of next-generation products. Innovations in automation, coupled with Industry 4.0 advancements, are also fueling the adoption of laser welding machines, as manufacturers seek to streamline processes and enhance productivity. The increasing emphasis on sustainability and energy efficiency in manufacturing operations is another significant factor encouraging industries to shift toward laser welding technologies, given their ability to reduce waste, optimize material usage, and deliver consistent results.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.7 Billion |

| Forecast Value | $4.5 Billion |

| CAGR | 5.2% |

Laser welding technology is widely preferred over conventional welding methods for its superior precision, efficiency, and adaptability. The market is segmented by laser technology, with fiber lasers, CO2 lasers, diode lasers, and other variants forming the core product types. Among these, fiber lasers held a dominant share, valued at USD 1.2 billion in 2024, and are projected to reach USD 1.8 billion by 2034. Fiber lasers are highly favored across industries for their exceptional beam quality, energy efficiency, and reduced operational costs. These lasers are capable of welding intricate and delicate components without causing distortions, making them indispensable in sectors like automotive, medical device manufacturing, and electronics where precision is paramount.

Additionally, the market is segmented based on end-use industries, including automotive, medical, electronics, aerospace, and jewelry. The electronics segment, valued at USD 0.9 billion in 2024, is set to grow at a CAGR of 3.8% during the forecast period, driven by the demand for precision welding in compact and complex components such as semiconductors, circuit boards, and microelectronics.

The U.S. laser welding machine market, generating USD 540 million in 2024, is forecast to expand at a CAGR of 5.3% between 2025 and 2034, fueled by advancements in automation, electric vehicle manufacturing, and semiconductor production, making the U.S. a leading hub for fiber laser technology.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definition

- 1.2 Base estimates & calculations

- 1.3 Forecast parameters

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factors affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.1.7 Retailers

- 3.2 Impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Expansion of the automotive industry

- 3.2.1.2 Surge in manufacturing activities

- 3.2.1.3 Technological advancements in laser welding

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment and maintenance costs

- 3.2.2.2 Limited skilled workforce for operation and programming

- 3.2.1 Growth drivers

- 3.3 Technology & innovation landscape

- 3.4 Growth potential analysis

- 3.5 Regulatory landscape

- 3.6 Pricing analysis

- 3.7 Porter's analysis

- 3.8 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Technology, 2021 – 2034, (USD Billion) (Million Units)

- 5.1 Key trends

- 5.2 Fiber lasers

- 5.3 CO2 lasers

- 5.4 Diode lasers

- 5.5 Others

Chapter 6 Market Estimates & Forecast, By End Use, 2021 – 2034, (USD Billion) (Million Units)

- 6.1 Key trends

- 6.2 Automotive

- 6.3 Medical

- 6.4 Electronics

- 6.5 Aerospace & defense

- 6.6 Jewelry

- 6.7 Others

Chapter 7 Market Estimates & Forecast, By Distribution Channel, 2021 – 2034, (USD Billion) (Million Units)

- 7.1 Key trends

- 7.2 Direct

- 7.3 Indirect

Chapter 8 Market Estimates & Forecast, By Region, 2021 – 2034, (USD Billion) (Million Units)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 The U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Russia

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 South Korea

- 8.4.5 Australia

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.6 MEA

- 8.6.1 Saudi Arabia

- 8.6.2 UAE

- 8.6.3 South Africa

Chapter 9 Company Profiles (Business Overview, Financial Data, Product Landscape, Strategic Outlook, SWOT Analysis)

- 9.1 CHIRON Group

- 9.2 Coherent

- 9.3 Emerson Electric

- 9.4 Han's Laser Technology Industry Group

- 9.5 Huagong Laser Engineering

- 9.6 IPG Photonics

- 9.7 Jenoptik

- 9.8 KEYENCE

- 9.9 Laser Technologies

- 9.10 Laser line

- 9.11 Laser Star Technologies

- 9.12 Penta Laser

- 9.13 Precitec

- 9.14 TRUMPF