|

시장보고서

상품코드

1740889

저밀도 폴리에틸렌 포장 시장 기회, 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Low-density Polyethylene Packaging (LDPE) Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

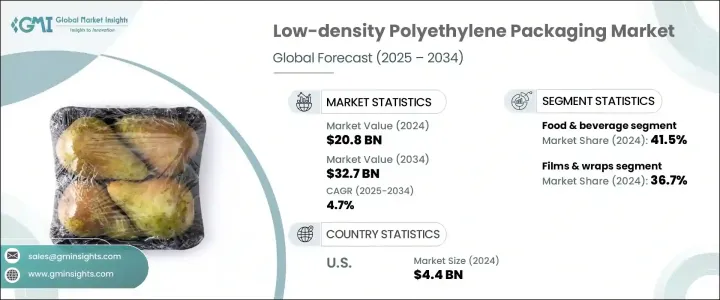

세계의 저밀도 폴리에틸렌 포장 시장은 2024년에 208억 달러로 평가되었고 식품, 의약품, 퍼스널케어 업계 전체의 견조한 수요에 견인되어 CAGR 4.7%를 나타내 2034년에는 327억 달러에 이를 것으로 추정되고 있습니다.

이 성장은 소비자 부문과 산업 부문 모두에서 저밀도 폴리에틸렌(LDPE) 포장의 용도 확대를 반영합니다. 기업도 소비자도 제품의 안전성과 유통 기한을 우선하는 가운데, LDPE 포장은 다양한 공급 체인으로 제품의 무결성을 확보하는 데 있어서 중요한 역할을 하고 있습니다.

또한 전자상거래와 디지털 쇼핑 플랫폼의 동향이 높아져 제품을 무손실로 유지하면서 운송이나 핸들링의 스트레스를 견딜 수 있는 연포장 재료에 대한 수요를 뒷받침하고 있습니다. 규제의 초점이 증가함에 따라 시장의 잠재력이 더욱 높아지고 있습니다. 환경 의식이 높은 소비자와 규제 당국 사이에서 지지를 모으고 있습니다. 업무 효율과 브랜드 어필의 향상을 목표로 한 포장 형태와 소재의 혁신이 세계의 많은 포장 기업의 전략적 방향성을 형성하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 208억 달러 |

| 예측 금액 | 327억 달러 |

| CAGR | 4.7% |

LDPE는 내습성과 유연성이 뛰어나므로 식음료 분야에서 널리 사용되고 있으며, 신선한 제품의 포장에 최적입니다. 특히 신흥경제국에서 금방 먹을 수 있는 음식과 1회분의 식품에 크게 기울어져 있으며 신선도와 안전성을 유지하기 위해 LDPE 필름과 용기에 의존하고 있습니다.

의약품 및 퍼스널케어 분야에서는 헬스케어 의식 증가, 세계의 노령화, 개인의 건강 증진에의 지출 증가에 의해 LDPE 포장이 계속 지지를 모으고 있습니다 시프트가 가속하고 있습니다. LDPE는 비용 효율적이고 가공이 용이하기 때문에 제조업체가 엄격한 안전 기준과 포장 기준을 충족하는데 있어 중심적인 역할을 하고 있습니다.

그러나 시장은 무역 관련 혼란이라는 역풍에 직면하고 있습니다. 트럼프 행정부에서 도입된 철강, 알루미늄, 중국산 부품에 대한 관세는 포장재 공급망 전반에 파급 효과를 일으켰습니다. 이러한 정책은 LDPE 수지와 완제품 포장재의 비용 상승으로 이어져 생산 비용에 상승 압력을 가하고 궁극적으로 소비자 가격을 인상했습니다.

제품 세분화에서 필름 및 랩 카테고리는 2024년 시장 점유율 36.7%를 차지했습니다. 저렴하고 사용하기 쉽기 때문에 제품의 안전성을 확보하면서 포장 비용을 최적화하고 싶은 기업에 선호되고 있습니다.

2024년에는 식음료 산업이 압도적인 최종 용도 부문으로 부상하여 41.5% 시장 점유율을 차지했습니다. 소비자가 빠르고 외출이 많은 라이프 스타일을 받아들이고 있기 때문에 LDPE와 같은 유연하고 내구성 있는 포장에 대한 의존도는 특히 포장 식품의 소비가 급증하는 신흥 시장에서 높아질 것으로 예측됩니다.

미국의 저밀도 폴리에틸렌 포장 시장은 2024년에 44억 달러로 평가되었습니다. 동시에, 지속 가능한 포장에 대한 관심 증가는 제조업체가 재활용 LDPE 솔루션에 투자하도록 촉구하고 있습니다.

세계의 저밀도 폴리에틸렌 포장 시장의 주요 기업은 Constantia Flexibles, Berry Global Inc. Sealed Air, Amcor plc 등이 있습니다. 이러한 기업은 경쟁력을 유지하기 위해 기술적인 업그레이드와 지속 가능한 실천을 활용하고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 트럼프 정권의 관세 분석

- 무역에 미치는 영향

- 무역량의 혼란

- 보복 조치

- 업계에 미치는 영향

- 공급측의 영향

- 주요 원재료의 가격 변동

- 공급망 재구성

- 생산 비용에 미치는 영향

- 수요측의 영향(판매가격)

- 최종 시장에의 가격 전달

- 시장 점유율 동향

- 소비자의 반응 패턴

- 공급측의 영향

- 영향을 받는 주요 기업

- 전략적인 업계의 대응

- 공급망 재구성

- 가격 설정 및 제품 전략

- 정책관여

- 전망과 향후 검토 사항

- 무역에 미치는 영향

- 영향요인

- 성장 촉진요인

- 포장 식품 및 음료 부문의 성장

- 의약품과 퍼스널케어 수요 증가

- 전자상거래와 소매 유통 확대

- 산업 및 농업 용도에서의 채용 증가

- 경량화와 재료 효율

- 업계의 잠재적 위험 및 과제

- 환경 문제와 규제 압력

- 리사이클율이 낮고, 순환성이 한정되어 있습니다.

- 성장 촉진요인

- 성장 가능성 분석

- 기술과 혁신의 상황

- 특허 분석

- 주요 뉴스와 대처

- 향후 시장 동향

- Porter's Five Forces 분석

- PESTEL 분석

- 규제 상황

제4장 경쟁 구도

- 서론

- 기업의 시장 점유율 분석

- 경쟁 포지셔닝 매트릭스

- 전략적 전망 매트릭스

제5장 시장 추계·예측 : 포장 형태별(2021-2034년)

- 주요 동향

- 가방 및 파우치

- 병 및 용기

- 필름 및 랩

- 튜브

- 기타

제6장 시장 추계·예측 : 최종 용도별(2021-2034년)

- 주요 동향

- 식음료

- 퍼스널케어 및 화장품

- 전기 및 전자 기기

- 소비재

- 의약품

- 전자상거래

- 기타

제7장 시장 추계·예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 영국

- 독일

- 프랑스

- 이탈리아

- 스페인

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주

- 라틴아메리카

- 브라질

- 멕시코

- 중동 및 아프리카

- 남아프리카

- 사우디아라비아

- 아랍에미리트(UAE)

제8장 기업 프로파일

- Amcor plc

- BENZ Packaging

- Berry Global Inc.

- Constantia Flexibles

- EPL Limited

- FKuR

- Inteplast Group

- Origin Pharma Packaging

- RKW Group

- SABIC

- Sealed Air

- Silgan Holdings

- Sirane Group

- Sonoco Products Company

- Strobel GmbH

- TC Transcontinental

- Thermo Fisher Scientific Inc.

- Westlake Corporation

The Global Low-Density Polyethylene Packaging Market was valued at USD 20.8 billion in 2024 and is estimated to grow at a CAGR of 4.7% to reach USD 32.7 billion by 2034, driven by robust demand across food, pharmaceutical, and personal care industries. This growth reflects the expanding applications of LDPE packaging in both consumer and industrial sectors. With the global packaging industry rapidly evolving, LDPE remains a preferred material due to its flexibility, durability, low production cost, and high resistance to moisture. As businesses and consumers alike prioritize product safety and shelf-life, LDPE packaging plays a key role in ensuring product integrity across various supply chains.

The rising trend of e-commerce and digital shopping platforms also fuels the demand for flexible packaging materials that can withstand shipping and handling stress while keeping products intact. In addition, the shift toward lightweight, space-saving packaging that helps reduce transportation costs is making LDPE a go-to material for manufacturers. Growing regulatory focus on food safety and packaging hygiene is further enhancing the market potential. Amid ongoing efforts toward sustainability, manufacturers are now working on producing recyclable and eco-friendly LDPE packaging solutions, which are gaining traction among environmentally conscious consumers and regulators. Innovation in packaging formats and materials, aimed at boosting operational efficiency and brand appeal, is shaping the strategic direction of many packaging firms globally.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $20.8 billion |

| Forecast Value | $32.7 billion |

| CAGR | 4.7% |

LDPE is widely used in the food and beverage sector due to its moisture resistance and flexibility, making it ideal for packaging perishable products. The increasing demand for convenience food, driven by changing lifestyles and urbanization, is significantly boosting the use of LDPE-based packaging. Consumers are leaning heavily toward ready-to-eat meals and single-serve food products, especially in developing economies, which rely on LDPE films and containers to maintain freshness and safety. With its hygienic attributes, LDPE ensures an extended shelf life for food items, aligning with modern consumption habits and distribution models.

In the pharmaceutical and personal care segments, LDPE packaging continues to gain traction due to rising healthcare awareness, an aging global population, and higher spending on personal wellness. The heightened focus on hygiene and contamination prevention, particularly in the post-pandemic landscape, is accelerating the shift toward single-use and tamper-proof packaging formats. LDPE, being cost-effective and easy to process, is playing a central role in helping manufacturers meet stringent safety and packaging standards. From ointment tubes and medicine pouches to personal care sachets, LDPE is proving its versatility and effectiveness across multiple product categories.

However, the market has faced headwinds in the form of trade-related disruptions. Tariffs on steel, aluminum, and Chinese components introduced during the Trump administration caused a ripple effect throughout the packaging supply chain. These policies led to increased costs for LDPE resins and finished packaging materials, putting upward pressure on production expenses and ultimately raising consumer prices. Trade tensions with key partners like Mexico and Canada also restricted raw material flow, challenging the availability of essential components and adding to logistical complexity for manufacturers.

In terms of product segmentation, the films and wraps category accounted for a 36.7% market share in 2024. These products are widely used in food packaging, industrial wrapping, and e-commerce shipping due to their adaptability and moisture barrier properties. Their affordability and ease of use make them a preferred choice for businesses looking to optimize packaging costs while ensuring product safety. As the need for protective packaging grows across sectors, this segment continues to thrive.

The food and beverage industry emerged as the dominant end-use segment in 2024, holding a 41.5% market share. LDPE packaging is extensively used to safeguard freshness and hygiene, making it indispensable for frozen foods, snacks, dairy, and processed meals. As consumers embrace fast-paced, on-the-go lifestyles, the reliance on flexible and durable packaging like LDPE is only expected to grow, especially in emerging markets where packaged food consumption is surging.

The United States Low-Density Polyethylene (LDPE) Packaging Market was valued at USD 4.4 billion in 2024. Growth here is primarily driven by consistent demand from the food, pharmaceutical, and e-commerce sectors. Technological advancements in processing and the rising focus on safety, hygiene, and regulatory compliance are driving innovation. At the same time, increased interest in sustainable packaging is pushing manufacturers to invest in recycled LDPE solutions. These efforts are enabling businesses to meet customer expectations while aligning with global sustainability goals.

Major players in the global LDPE packaging market include Constantia Flexibles, Berry Global Inc., Sealed Air, and Amcor plc. These companies are leveraging technological upgrades and sustainable practices to stay competitive. Key strategies involve expanding product lines, improving supply chain resilience, and enhancing the recyclability of LDPE products to address environmental concerns and evolving regulatory frameworks.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact

- 3.2.2.1.1 Price volatility in key raw material

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact

- 3.2.3 key companies impacted

- 3.2.4 strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Impact forces

- 3.3.1 Growth drivers

- 3.3.1.1 Growth in packaged food & beverage sector

- 3.3.1.2 Rising demand in pharmaceuticals & personal care

- 3.3.1.3 Expansion of e-commerce & retail distribution

- 3.3.1.4 Increased adoption in industrial and agricultural applications

- 3.3.1.5 Lightweighting and material efficiency

- 3.3.2 Industry pitfalls & challenges

- 3.3.2.1 Environmental concerns and regulatory pressure

- 3.3.2.2 Low recycling rate and limited circularity

- 3.3.1 Growth drivers

- 3.4 Growth potential analysis

- 3.5 Technological & innovation landscape

- 3.6 Patent analysis

- 3.7 Key news and initiatives

- 3.8 Future market trends

- 3.9 Porter's analysis

- 3.10 PESTEL analysis

- 3.11 Regulatory landscape

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Packaging Type, 2021 - 2034 (USD Billion & Kilo Tons)

- 5.1 Key trends

- 5.2 Bags & pouches

- 5.3 Bottles & containers

- 5.4 Films & wraps

- 5.5 Tubes

- 5.6 Others

Chapter 6 Market Estimates & Forecast, By End Use, 2021 - 2034 (USD Billion & Kilo Tons)

- 6.1 Key trends

- 6.2 Food and beverages

- 6.3 Personal care & cosmetics

- 6.4 Electricals & electronics

- 6.5 Consumer goods

- 6.6 Pharmaceuticals

- 6.7 E-commerce

- 6.8 Others

Chapter 7 Market Estimates & Forecast, By Region, 2021 - 2034 (USD Billion & Kilo Tons)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.3 Europe

- 7.3.1 UK

- 7.3.2 Germany

- 7.3.3 France

- 7.3.4 Italy

- 7.3.5 Spain

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 India

- 7.4.3 Japan

- 7.4.4 South Korea

- 7.4.5 Australia

- 7.5 Latin America

- 7.5.1 Brazil

- 7.5.2 Mexico

- 7.6 MEA

- 7.6.1 South Africa

- 7.6.2 Saudi Arabia

- 7.6.3 UAE

Chapter 8 Company Profiles

- 8.1 Amcor plc

- 8.2 BENZ Packaging

- 8.3 Berry Global Inc.

- 8.4 Constantia Flexibles

- 8.5 EPL Limited

- 8.6 FKuR

- 8.7 Inteplast Group

- 8.8 Origin Pharma Packaging

- 8.9 RKW Group

- 8.10 SABIC

- 8.11 Sealed Air

- 8.12 Silgan Holdings

- 8.13 Sirane Group

- 8.14 Sonoco Products Company

- 8.15 Strobel GmbH

- 8.16 TC Transcontinental

- 8.17 Thermo Fisher Scientific Inc.

- 8.18 Westlake Corporation