|

시장보고서

상품코드

1801851

저항 점용접기 시장 : 기회, 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Resistance Spot Welding Machines Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

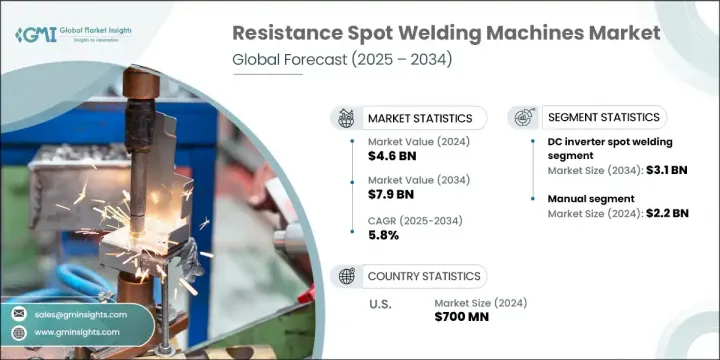

세계의 저항 점용접기 시장 규모는 2024년에 46억 달러에 달하고, CAGR 5.8%로 성장할 전망이며 2034년에는 79억 달러에 이를 것으로 예측되고 있습니다.

이러한 성장은 제조 자동화의 지속적인 발전, 특히 자동차, 항공우주, 가전제품 생산과 같은 고생산성 산업에서의 발전에 힘입고 있습니다. 제조업체들은 품질, 효율성 및 처리량을 최적화하기 위해 디지털 제어 장치와 로봇 용접 시스템을 통합하고 있습니다. 아시아태평양 지역의 유리한 산업 정책과 제조업 확장은 저항 스폿 용접을 대량 생산 환경에서 핵심 생산 공정으로 더욱 자리매김하게 했습니다.

전기차 보급이 증가함에 따라 경량 다중 금속 구조물 및 배터리 부품 조립에 중요한 역할을 하는 저항 스폿 용접에 대한 수요가 더욱 높아지고 있습니다. 이 공정의 고속 작동, 신뢰성 및 비용 효율성은 구조적 접합 용도에서 여전히 필수적입니다. 저항 용접은 또한 고강도 강철 및 알루미늄과 같은 경량 소재로의 엔지니어링 전환을 지원하며, 낮은 열 변형과 강한 용접 접합부를 제공하여 최근 설계 요구 사항에 필수적인 속성을 갖추고 있습니다. 그 결과, 전 세계 OEM 및 1차 공급업체들은 생산 및 소재 유연성 요구를 충족시키기 위해 기존 및 고급 RSW 기계에 지속적으로 투자하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 46억 달러 |

| 예측 금액 | 79억 달러 |

| CAGR | 5.8% |

DC 인버터 부문은 2024년 18억 달러를 기록했으며, 2034년까지 31억 달러에 도달할 것으로 예상됩니다. 이 기계들은 AC 기반 장비에 비해 향상된 정밀도, 더 빠른 전류 응답 및 더 짧은 용접 사이클을 제공합니다. 인버터 기술은 일관성을 개선하고 운영 비용을 낮추며 최대 30% 적은 에너지를 소비하여 지속 가능성과 효율성을 추구하는 제조업체에게 점점 더 매력적으로 만들고 있습니다.

수동 점용접 부문은 2024년 22억 달러를 차지하며 49.1%의 점유율을 확보했습니다. 이러한 수요의 상당한 부분은 라틴 아메리카, 아시아, 동유럽 등의 지역 중소기업에서 비롯됩니다. 이들 업체는 경제성, 쉬운 조작성, 최소한의 유지보수 필요성 때문에 수동식 장비를 주로 사용합니다. 수동식 스폿 용접기는 소량 생산, 다양한 부품 크기, 빈번한 설비 변경이 필요한 산업 분야에서 널리 사용됩니다. HVAC 제작, 맞춤형 금속 가공, 가구 생산과 같은 분야는 저량 생산이나 특수 작업에서 적응성과 낮은 운영 비용을 이유로 수동 시스템을 계속 선호하고 있습니다.

미국의 저항 점용접기 시장은 2024년 7억 달러를 기록했으며, 2034년까지 연평균 성장률(CAGR) 4.9%로 성장할 것으로 예상됩니다. 미국은 구조용 용접이 중요한 자동차 및 방위 용도 분야의 전 세계 제조 허브로 자리매김하고 있습니다. 전기자동차 생산의 가속화로 국내 수요도 강화되었으며, 주요 자동차 제조사들은 배터리 모듈 및 차체(BIW) 구조물 같은 핵심 부품에 점용접기를 전개하고 있습니다. 또한 방위 산업 및 생산 능력 국내 복귀에 대한 연방 정부의 투자가 현지 OEM 및 공급업체의 RSW 시스템 수요를 꾸준히 증가시키는 데 기여했습니다.

저항 점용접기 시장의 주요 기업으로는 미야치 유니텍(AMADA WELD TECH), CenterLine(Windsor) Ltd., 파나소닉 용접 시스템즈 주식회사, Nimac GmbH, Automation International, Inc. 등이 모두 이 부문에서 주도적 지위를 유지하고 있습니다. 저항 점용접 시장의 선도 기업들은 자동화, 에너지 효율성, 고급 제어 시스템에 대한 투자를 통해 경쟁 엣지를 강화하고 있습니다. 자동차 OEM 및 산업 제조업체와의 전략적 파트너십을 통해 진화하는 소재 및 설계 요구 사항을 충족하는 맞춤형 용접 솔루션을 공동 개발할 수 있습니다. 여러 제조업체들은 스마트 모니터링, 예측 유지보수, AI 기반 용접 정밀도를 갖춘 향후 인버터 기반 시스템을 도입하기 위해 연구 개발 활동을 확대되고 있습니다. 또한 서비스 네트워크 확대 및 고성장 지역에서의 생산 현지화를 통해 더 빠른 지원과 낮은 유통 비용을 실현하고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 산업 고찰

- 생태계 분석

- 공급자의 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 주는 요인

- 산업에 미치는 영향요인

- 성장 촉진요인

- 산업의 잠재적 리스크 및 과제

- 기회

- 성장 가능성 분석

- 장래 시장 동향

- 기술과 혁신의 상황

- 현재의 기술 동향

- 신흥기술

- 가격 동향

- 지역별·용접 재료별

- 규제 상황

- 표준 및 규정 준수 요건

- 지역 규제 틀

- 인증기준

- Porter's Five Forces 분석

- PESTEL 분석

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 지역별

- 북미

- 유럽

- 아시아태평양

- 중동 및 아프리카

- 라틴아메리카

- 지역별

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 합병과 인수

- 파트너십 및 협업

- 신제품 발매

- 확대 계획

제5장 시장 추정 및 예측 : 기술별(2021-2034년)

- 주요 동향

- AC 저항 점용접

- DC 인버터 점용접

- 커패시터 방전 점용접

- 서보건 점용접

제6장 시장 추정 및 예측 : 용접 재료별(2021-2034년)

- 주요 동향

- 연강

- 스테인리스

- 알루미늄

- 아연 도금 강철

- 구리와 합금

- 기타(고강도 저합금강(HSLA), 이종 금속 복합강, 기타)

제7장 시장 추정 및 예측 : 용접 두께별(2021-2034년)

- 주요 동향

- 2mm 미만

- 2-5mm

- 5mm 초과

제8장 시장 추정 및 예측 : 전원별(2021-2034년)

- 주요 동향

- 단상 전원

- 3상 전원

- 직류 전원

제9장 시장 추정 및 예측 : 자동화 레벨별(2021-2034년)

- 주요 동향

- 수동

- 반자동

- 자동

제10장 시장 추정 및 예측 : 최종 이용 산업별(2021-2034년)

- 주요 동향

- 자동차

- 제조업

- 항공우주 및 방위

- 전자 및 반도체

- 건설

- 농업 기기

- 기타

제11장 시장 추정 및 예측 : 유통 채널별(2021-2034년)

- 주요 동향

- 직접

- 간접

제12장 시장 추정 및 예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 이탈리아

- 스페인

- 네덜란드

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주

- 라틴아메리카

- 브라질

- 멕시코

- 아르헨티나

- 중동 및 아프리카

- 아랍에미리트(UAE)

- 사우디아라비아

- 남아프리카

제13장 기업 프로파일

- ARO Welding Technologies SAS

- Automation International, Inc.

- CenterLine(Windsor) Ltd.

- Dengensha Manufacturing Co., Ltd.

- Guangzhou CEA Welding Equipment Co., Ltd.

- Heron Intelligent Equipment Co., Ltd.

- Janda Company, Inc.

- Miyachi Unitek(AMADA WELD TECH)

- Nimak GmbH

- Panasonic Welding Systems Co., Ltd.

- TJ Snow Company, Inc.

- TECNA SpA

The Global Resistance Spot Welding Machines Market was valued at USD 4.6 billion in 2024 and is estimated to grow at a CAGR of 5.8% to reach USD 7.9 billion by 2034. This growth is being fueled by continued advancements in manufacturing automation, especially in high-output industries such as automotive, aerospace, and appliance production. Manufacturers are integrating digital controls and robotic welding systems to optimize quality, efficiency, and throughput. Favorable industrial policies and the expansion of manufacturing in the Asia-Pacific region have further positioned resistance spot welding as a key process in high-volume production environments.

As electric vehicle adoption rises, demand for resistance spot welding intensifies due to its relevance in assembling lightweight, multi-metal structures and battery components. The method's high-speed operation, reliability, and cost-effectiveness continue to make it indispensable in structural joining applications. Resistance welding also supports engineering shifts toward lightweight materials like high-strength steel and aluminum, offering low thermal distortion and strong weld joints-attributes crucial to modern design requirements. As a result, OEMs and Tier-1 suppliers globally continue to invest in both traditional and advanced RSW machines to meet production and material flexibility demands.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $4.6 Billion |

| Forecast Value | $7.9 Billion |

| CAGR | 5.8% |

The DC inverter segment generated USD 1.8 billion during 2024 and is projected to reach USD 3.1 billion by 2034. These machines provide enhanced precision, faster current response, and shorter weld cycles compared to AC-based equipment. Inverter technology improves consistency, lowers operational costs, and consumes up to 30% less energy, making it increasingly attractive for manufacturers pursuing sustainability and efficiency.

The manual spot-welding segment accounted for USD 2.2 billion in 2024, securing a 49.1% share. A significant portion of this demand stems from small and medium enterprises in regions such as Latin America, Asia, and Eastern Europe. These operations often rely on manual machines for their affordability, ease of operation, and minimal maintenance needs. Manual spot welders are widely used in small-batch production, varied part sizes, and industries require frequent setup changes. Sectors such as HVAC fabrication, custom metalwork, and furniture production continue to favor manual systems for their adaptability and low operating cost in low-volume or specialized tasks.

United States Resistance Spot Welding Machines Market generated USD 700 million in 2024 and is expected to grow at a CAGR of 4.9% through 2034. The US remains a global manufacturing hub for automotive and defense applications, where structural welding is critical. The accelerated growth of electric vehicle production has also strengthened domestic demand, with major automotive manufacturers deploying spot welding machines for key components like battery modules and BIW structures. Additionally, federal investments in defense and reshoring production capacity have supported a steady increase in demand for RSW systems from local OEMs and suppliers.

Major Resistance Spot Welding Machines Market players include Miyachi Unitek (AMADA WELD TECH), CenterLine (Windsor) Ltd., Panasonic Welding Systems Co., Ltd., Nimak GmbH, and Automation International, Inc., all of which continue to hold leading positions in this space. Leading companies in the resistance spot welding machines market are enhancing their competitive edge through investments in automation, energy efficiency, and advanced control systems. Strategic partnerships with automotive OEMs and industrial manufacturers allow for collaborative development of tailored welding solutions that meet evolving material and design needs. Several manufacturers are scaling up their R&D activities to introduce next-generation inverter-based systems with smart monitoring, predictive maintenance, and AI-driven welding precision. Additionally, expanding service networks and localization of production in high-growth regions enable faster support and lower distribution costs.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Technology

- 2.2.3 Material Welded

- 2.2.4 Welding Thickness

- 2.2.5 Power Supply

- 2.2.6 Automation Level

- 2.2.7 End Use Industry

- 2.2.8 Distribution Channel

- 2.3 CXO perspective: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry Impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls & challenges

- 3.2.3 Opportunities

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region and materials welded

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter’s analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Middle East and Africa

- 4.2.1.5 Latin America

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Technology, 2021 - 2034 (USD Billion) (Units)

- 5.1 Key trends

- 5.2 AC Resistance Spot Welding

- 5.3 DC Inverter Spot Welding

- 5.4 Capacitor Discharge Spot Welding

- 5.5 Servo-Gun Spot Welding

Chapter 6 Market Estimates & Forecast, By Material Welded, 2021 - 2034, (USD Billion) (Units)

- 6.1 Key trends

- 6.2 Mild Steel

- 6.3 Stainless Steel

- 6.4 Aluminum

- 6.5 Galvanized Steel

- 6.6 Copper & Alloys

- 6.7 Others (High Strength Low Alloy (HSLA) Steel, Dissimilar Metal Combination, etc.)

Chapter 7 Market Estimates & Forecast, By Welding Thickness, 2021 - 2034, (USD Billion) (Units)

- 7.1 Key trends

- 7.2 Up to 2 mm

- 7.3 2 - 5 mm

- 7.4 Above 5 mm

Chapter 8 Market Estimates & Forecast, By Power Supply, 2021 - 2034, (USD Billion) (Units)

- 8.1 Key trends

- 8.2 Single-phase Power Supply

- 8.3 Three-phase Power Supply

- 8.4 Direct Current Power Supply

Chapter 9 Market Estimates & Forecast, By Automation Level, 2021 - 2034, (USD Billion) (Units)

- 9.1 Key trends

- 9.2 Manual

- 9.3 Semi-automatic

- 9.4 Automatic

Chapter 10 Market Estimates & Forecast, By End Use Industry, 2021 - 2034, (USD Billion) (Units)

- 10.1 Key trends

- 10.2 Automotive

- 10.3 Manufacturing

- 10.4 Aerospace and Defense

- 10.5 Electronics and Semiconductors

- 10.6 Construction

- 10.7 Agricultural Equipment

- 10.8 Others

Chapter 11 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034, (USD Billion) (Units)

- 11.1 Key trends

- 11.2 Direct

- 11.3 Indirect

Chapter 12 Market Estimates & Forecast, By Region, 2021 - 2034, (USD Billion) (Units)

- 12.1 Key trends

- 12.2 North America

- 12.2.1 U.S.

- 12.2.2 Canada

- 12.3 Europe

- 12.3.1 Germany

- 12.3.2 U.K.

- 12.3.3 France

- 12.3.4 Italy

- 12.3.5 Spain

- 12.3.6 Netherlands

- 12.4 Asia Pacific

- 12.4.1 China

- 12.4.2 India

- 12.4.3 Japan

- 12.4.4 South Korea

- 12.4.5 Australia

- 12.5 Latin America

- 12.5.1 Brazil

- 12.5.2 Mexico

- 12.5.3 Argentina

- 12.6 MEA

- 12.6.1 UAE

- 12.6.2 Saudi Arabia

- 12.6.3 South Africa

Chapter 13 Company Profiles (Business Overview, Financial Data, Product Landscape, Strategic Outlook, SWOT Analysis)

- 13.1 ARO Welding Technologies SAS

- 13.2 Automation International, Inc.

- 13.3 CenterLine (Windsor) Ltd.

- 13.4 Dengensha Manufacturing Co., Ltd.

- 13.5 Guangzhou CEA Welding Equipment Co., Ltd.

- 13.6 Heron Intelligent Equipment Co., Ltd.

- 13.7 Janda Company, Inc.

- 13.8 Miyachi Unitek (AMADA WELD TECH)

- 13.9 Nimak GmbH

- 13.10 Panasonic Welding Systems Co., Ltd.

- 13.11 T. J. Snow Company, Inc.

- 13.12 TECNA S.p.A.