|

시장보고서

상품코드

1693720

보틀 캡핑 장비 : 시장 점유율 분석, 산업 동향과 통계, 성장 예측(2025-2030년)Bottle-Capping Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

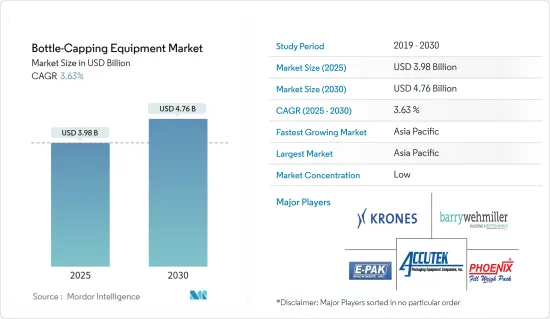

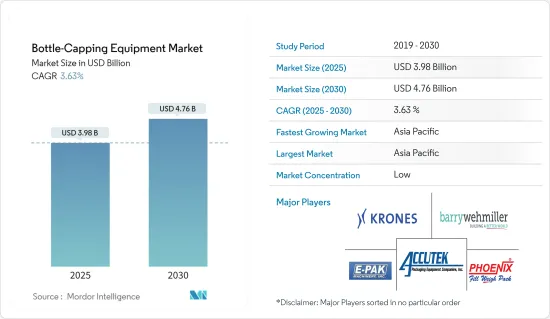

보틀 캡핑 장비 시장 규모는 2025년에 39억 8,000만 달러로 예측되며, 예측 기간(2025-2030년) 동안 3.63%의 연평균 복합 성장률(CAGR)로 2030년에는 47억 6,000만 달러에 달할 것으로 예측됩니다.

주요 하이라이트

- 보틀 캡핑 장비는 병마개 자동화에 있어 매우 중요한 역할을 하며, 병마개가 정확하고 확실하게 장착되도록 보장합니다. 다양한 최종 사용 산업에서 안전한 병 마감을 요구하는 것은 이 장비의 필요성을 증가시키고 있습니다.

- 다양한 병 크기와 유형에 대응하는 캡핑 장비는 현재 종종 클린 인 플레이스(CIP) 기술을 통합하고 있습니다. 이 기능은 식품 가공 및 제약 산업에서 널리 사용되고 있으며, 오염을 방지하기 위해 기계를 살균합니다. 완전 자동화된 CIP 기술은 주요 오염 위험인 인적 접촉을 크게 줄입니다. 이러한 기술 혁신은 향후 몇 년 동안 시장을 강화할 준비가 되어 있습니다.

- 주로 제약, 음료, 식품, 화학 분야에서 사용되는 보틀 캡핑 장비는 포장 시 병을 확실하게 밀봉합니다. 이 기계는 제조 공정을 강화할 뿐만 아니라 품질과 위생을 우선시하기 때문에 수요가 증가하고 있습니다.

- 빠르게 움직이는 음료 및 의약품에 대한 수요가 증가함에 따라 제조업체는 생산 라인의 속도를 높이고 있습니다. 따라서 부피와 무게의 정확성을 잃지 않고 빠른 밀봉을 실현하는 보틀 캡핑 장비에 대한 요구가 증가하고 있습니다.

- 플라스틱, 유리, 금속 등 다양한 병에 대응할 수 있는 보틀 캡핑 장비입니다. 최근 가처분 소득 증가와 건강 지향적 인 소비자 증가로 가공 식품에 대한 수요가 급증하고 있습니다. 이러한 추세는 음료 및 식품 부문의 성장에 박차를 가하여 보틀 캡핑 장비에 대한 수요를 더욱 증가시키고 있습니다.

- 포장 산업을 설립하려면 주로 높은 설비 비용으로 인해 많은 설비 투자가 필요합니다. 그 결과, 설치에 따른 막대한 유지보수 비용이 문제가 되어 보틀 캡핑 장비 시장의 성장을 저해하고 있습니다.

보틀 캡핑 장비 시장 동향

제약 및 화학 산업이 첨단 병마개 솔루션에 대한 수요를 주도하고 있습니다.

- 변조 방지 캡에 대한 수요는 제약 및 화학 부문에서 급증하고 있습니다. 기업들은 유통기한 연장을 약속하는 제품을 점점 더 많이 찾고 있습니다. 제조업체들이 제품 출하를 늘리면서 운송의 어려움을 견디고 다양한 환경 조건에서 무결성을 유지하도록 설계된 포장이 절실히 요구되고 있습니다.

- 병마개는 오염을 방지할 뿐만 아니라 의약품 포장에 적용되는 엄격한 국제 안전 기준을 충족합니다. 보틀 캡핑 장비의 진화하는 기능은 시장 성장을 가속합니다.

- Adinath International의 2023년 조사에 따르면, 의약품 안전에 있어 병뚜껑의 중요성이 강조되고 있습니다. 캡은 환경 오염 물질로부터 원소의 순도를 보호하는 보호막 역할을 합니다. 최신 캡 장비가 시장에서 받아들여지고 있는 것은 안전한 포장에 대한 업계의 노력을 강조하고 있습니다.

- 제약 회사는 성분의 섬세함을 고려하여 적절하게 밀봉 된 멸균 병을 우선시합니다. 제품의 안전성을 유지하기 위해 이들 기업은 첨단 병마개 공정에 주목하고 있으며, 많은 시장 진출기업들이 제품 품질을 향상시키기 위해 특별한 메커니즘을 제공합니다.

- 2024년 6월, 셰메쉬 오토메이션은 주력 제품인 Attilus 연속 캡핑 장비의 출시 2주년을 맞이했습니다. Attilus는 통합 로봇 공학 및 최첨단 비전 시스템을 통해 자동 캡, 펌프 및 트리거 선별에 있어 탁월한 유연성, 고속화 및 정확성을 보장합니다. 탁월한 정확성을 약속합니다. 버튼 하나만 누르면 캡 유형을 전환할 수 있어 포맷 부품을 추가할 필요가 없어 다운타임을 크게 줄이고 비용을 크게 절감할 수 있습니다.

- 유럽화학공업협회(Cefic)의 데이터에 따르면 2024년 상반기 세계 화학제품 생산량은 2023년 대비 6.1% 증가했습니다(화학제품월보(CMR) 2024년 10월호에서 보고). 화학제품 판매량에서 아시아가 세계를 선도하고 유럽과 북미가 그 뒤를 이었습니다. 미국에서는 화학 산업이 변화의 시기를 맞이하고 있으며, 포트폴리오 재구성, 공급망 재구성, 재료 혁신의 선구자 역할을 하고 있습니다. 이 큰 변화는 진화하는 고객 수요에 대한 대응이 주요 원인이며, 제품 제공에서 원료 선택에 이르기까지 모든 것에 영향을 미치고 있습니다. 이러한 기술 혁신의 결과로 제조업체들은 더 빠르고 효율적인 보틀 캡핑 장비를 도입하기 시작했습니다.

주요 산업 수요 증가가 아시아태평양 보틀 캡핑 장비 시장의 성장을 견인합니다.

- 최종 사용자 산업이 제조 시설을 확장하고 제약 회사가 수요를 확대함에 따라 아시아태평양의 보틀 캡핑 장비 시장은 예측 기간 동안 성장할 태세를 갖추고 있습니다.

- 세계적인 우유 생산의 선두주자인 인도에서는 소비자들의 관심이 높아지면서 병에 담긴 유제품공급이 급증하고 있습니다. 이러한 추세에 따라 유제품 공급업체들은 전국적으로 병 제조 공장에 대한 투자를 촉진하고 보틀 캡핑 장비에 대한 수요를 증가시키고 있습니다.

- 보틀 캡핑 장비 시장공급업체들은 생산 능력 증가와 함께 화학 및 비료 부문에 대한 대응을 강화하고 있습니다. 예를 들어, 2024년 11월, 정부 기업인 National Fertilizers Limited(NFL)는 Nangal 공장에서 나노 요소 생산 계획을 발표했으며, 첨단 나노 기술을 활용하여 매일 500ml의 나노 요소 1.5리터를 생산할 계획입니다. 이러한 노력은 화학, 제약, 유제품 산업 수요 증가와 함께 인도 시장 성장을 가속할 것으로 보입니다.

- 일본의 보틀 캡핑 장비 시장은 식품, 음료 및 제약 분야의 혁신적인 솔루션에 대한 수요 증가에 힘입어 꾸준한 성장세를 보이고 있습니다. 자동화의 발전, 주요 벤더의 존재감, 끊임없는 기술 혁신의 추구로 일본 시장은 더욱 활기를 띠고 있습니다.

- 지역 내 지속가능성에 대한 노력에 따라 최종 사용자 산업은 혁신적인 음료 포장을 개발하고 있습니다. 이는 물과 주스부터 탄산음료에 이르기까지 병에 담긴 음료에 대한 선호도가 높아짐에 따라 이 지역 시장 확대에 박차를 가하고 있습니다.

보틀 캡핑 장비 산업 개요

Barry-Wehmiller Group, Inc., E-PAK Machinery Inc., Tetra Pak International SA(Tetra Laval Group), Accutek Packaging Equipment Inc. Companies Inc., Phoenix Dison Tec LLC, Krones AG 등의 기업이 다양한 유형의 기계를 제공하고 고객에게 최고의 경험을 제공하고 광고에 많은 비용을 투자하고 있습니다.

- 2024년 9월, 배리 웨밀러 그룹은 BW Filling & Closing을 출범시켰습니다. 이 새로운 사업부는 기존의 충전 및 폐쇄 사업인 Pneumatic Scale Angelus와 Synerlink의 강점을 통합한 것입니다. 이 새로운 사업체는 이전 조직의 제품 및 서비스를 원활하게 통합하는 것을 목표로 하고 있습니다. 또한, 전 세계 고객에 대한 지원과 서비스를 강화하여 고객이 기대하는 고품질 제품을 지속적으로 제공할 수 있도록할 것입니다.

- 2024년 7월, ProMach Inc.는 캡 및 캡 처리 장비 전문 Zalkin의 제조 시설을 확장하여 유럽 시장에서 큰 움직임을 보였습니다. 이 확장은 생산 능력을 높이고 리드 타임을 단축하며 회사의 성장 궤도를 추진하는 것을 목표로 합니다. 프로마하의 유럽 포장 시장에 대한 약속은 분명하며, 이번 설비 증설은 일련의 투자 중 가장 최신의 투자입니다. 지난 3년 동안 회사는 스페인과 이탈리아에서 여러 기업을 인수했습니다.

기타 혜택

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간 애널리스트 지원

목차

제1장 서론

- 조사의 전제조건과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 인사이트

- 시장 개요

- 산업 생태계 분석

- 산업의 매력 - Porter의 Five Forces 분석

- 공급 기업의 교섭력

- 바이어의 교섭력

- 신규 진출업체의 위협

- 대체품의 위협

- 경쟁 기업간 경쟁 관계

- 지정학적 시나리오의 산업에 대한 영향 평가

- 가격 분석

- 수출입 분석

제5장 시장 역학

- 시장 성장 촉진요인

- 시장 성장 억제요인

제6장 시장 세분화

- 기술별

- 자동

- 반자동

- 캡 유형별

- ROPP Caps

- Screw Caps

- Snap-on-Caps

- Corks

- 최종사용자별

- 의약품

- 퍼스널케어 및 화장품

- 식품 및 음료

- 화학제품

- 자동차

- 기타

- 지역별

- 북미

- 미국

- 캐나다

- 유럽

- 영국

- 독일

- 프랑스

- 아시아

- 중국

- 인도

- 일본

- 호주 및 뉴질랜드

- 라틴아메리카

- 멕시코

- 브라질

- 중동 및 아프리카

- 아랍에미리트(UAE)

- 사우디아라비아

- 남아프리카공화국

- 북미

제7장 경쟁 구도

- 기업 개요

- E-PAK Machinery Inc.

- Accutek Packaging Equipment Companies Inc.

- Barry-Wehmiller Group, Inc.

- Phoenix Dison Tec LLC

- Krones AG

- LPE(Levapack)

- Closure Systems International Inc(CSI)

- Ronchi Mario S.p.A.

- Likai Technology Co., Ltd.

- ProMach Inc.

- Marchesini Group S.p.A.

제8장 투자 분석

제9장 시장의 미래

LSH 25.05.20The Bottle-Capping Equipment Market size is estimated at USD 3.98 billion in 2025, and is expected to reach USD 4.76 billion by 2030, at a CAGR of 3.63% during the forecast period (2025-2030).

Key Highlights

- Bottle-capping equipment plays a pivotal role in bottling automation, ensuring caps are applied accurately and securely. Various end-use industries' demand for secure bottle closures drives the need for this equipment.

- Capping machines, tailored for diverse bottle sizes and types, now often incorporate Clean-in-Place (CIP) technology. This feature, prevalent in food processing and pharmaceuticals, sanitizes the machine to prevent contamination. Fully automated, CIP technology significantly reduces human contact, a major contamination risk. Such innovations are poised to bolster the market in the coming years.

- Primarily utilized in the pharmaceutical, food & beverage, and chemical sectors, bottle-capping machines ensure bottles are securely sealed during packaging. These machines not only enhance the manufacturing process but also prioritize quality and sanitization, fueling their demand.

- As the need for fast-moving beverages and pharmaceuticals grows, manufacturers are ramping up production line speeds. This surge amplifies the need for bottle-capping equipment, ensuring swift sealing without compromising volumetric and weight accuracy.

- Whether for plastic, glass, or metal, bottle-capping machines cater to a variety of bottles. Recent years have seen a surge in demand for processed foods, driven by rising disposable incomes and health-conscious consumers. This trend has spurred growth in the food and beverage sector, further amplifying the demand for bottle-capping equipment.

- Establishing a packaging industry demands hefty capital investments, primarily due to high equipment costs. Consequently, the substantial maintenance expenses of the setup pose a challenge, hindering the growth of the bottle-capping equipment market.

Bottle-Capping Equipment Market Trends

Pharmaceutical and Chemical Industries Drive Demand for Advanced Bottle-Capping Solutions

- Demand for tamper-evident caps is surging in the pharmaceutical and chemical sectors, driven by the need for child-resistant and contamination-free packaging. Companies are increasingly seeking products that promise an extended shelf life. As manufacturers ramp up product shipments, there's a pressing need for packaging designed to endure transport challenges and maintain integrity across varied environmental conditions.

- Bottle capping not only prevents contamination but also aligns with the stringent international safety standards governing pharmaceutical packaging. The evolving features of bottle-capping equipment are set to propel market growth.

- A 2023 survey by Adinath International highlighted the paramount importance of bottle caps in pharmaceutical product safety. Acting as a shield, the cap safeguards elemental purity from environmental contaminants. The market's embrace of modern capping machines underscores the industry's commitment to safe packaging.

- Given the sensitivity of their ingredients, pharmaceutical companies prioritize properly capped sterilized bottles. To uphold product safety, these companies are turning to advanced bottle capping processes, with many market players offering specialized mechanisms to enhance product quality.

- In June 2024, Shemesh Automation celebrated the second anniversary of Attilus, its flagship continuous motion capping machine. Attilus boasts integrated robotics and a cutting-edge vision system, promising unparalleled flexibility, heightened speeds, and superior accuracy in sorting automatic caps, pumps, and triggers. With a simple button press, users can switch cap types, eliminating the need for additional format parts and significantly cutting down downtime, translating to substantial cost savings.

- According to data from Cefic, the European Chemical Industry Council, global chemical production rose by 6.1% in the first half of 2024 compared to 2023, as reported in the October 2024 edition of their Chemical Monthly Report (CMR). Asia leads the world in chemical sales, trailed by Europe and North America. In the United States, the chemical industry is undergoing a transformation, reshaping portfolios, reimagining supply chains, and pioneering material innovations. This significant shift is largely a response to evolving customer demands, influencing everything from product offerings to raw material selection. As a result of these innovations, manufacturers have commenced the deployment of faster and more efficient bottle-capping machines.

Rising Demand Across Key Industries Drives Growth in Asia Pacific Bottle-Capping Equipment Market

- As end-user industries expand their manufacturing facilities and pharmaceutical companies ramp up demand, the bottle-capping equipment market in the Asia Pacific is poised for growth during the forecast period.

- India, a global leader in milk production, is witnessing a surge in bottled dairy offerings, due to heightened consumer interest. This trend has prompted dairy vendors to invest in bottle-making plants across the country, bolstering the demand for bottle-capping equipment.

- With a boost in production capacity, vendors in the bottle-capping equipment market are increasingly catering to the chemical and fertilizer sectors. For instance, in November 2024, National Fertilizers Limited (NFL), a government enterprise, unveiled plans to produce nano urea at its Nangal plant, churning out 1.5 lakh bottles of 500 ml nano urea daily, leveraging advanced nanotechnology. Such initiatives, coupled with rising demand from the chemical, pharmaceutical, and dairy industries, are set to propel market growth in India.

- Japan's bottle-capping equipment market is on a steady growth trajectory, driven by a surge in demand for innovative solutions in the food, beverage, and pharmaceutical sectors. The country's market is further buoyed by increasing automation, a strong presence of leading vendors, and their relentless pursuit of innovation.

- In line with regional sustainability initiatives, end-user industries are rolling out innovative beverage packaging. This, combined with a rising appetite for bottled beverages-ranging from water and juices to carbonated drinks-is fueling the market's expansion in the region.

Bottle-Capping Equipment Industry Overview

The bottle-capping equipment market is fragemented with companies such as Barry-Wehmiller Group, Inc., E-PAK Machinery Inc., Tetra Pak International SA (Tetra Laval Group), Accutek Packaging Equipment Companies Inc., Phoenix Dison Tec LLC, and Krones AG offer the various types of machines, delivering the best experience to their customers and spending high on advertising.

- September 2024: Barry-Wehmiller Group, Inc. has launched BW Filling & Closing, a new division that consolidates the strengths of its legacy filling and closing businesses, Pneumatic Scale Angelus and Synerlink. This newly formed entity aims to seamlessly integrate the products and services of its predecessor organizations. Additionally, it is committed to enhancing global support and services for its customers, ensuring they continue to receive the high-quality products they've come to expect.

- July 2024: ProMach Inc. has made a significant move in the European market by expanding Zalkin's manufacturing facility, which specializes in capping and cap handling equipment. This expansion aims to boost production capacity, shorten lead times, and propel the company's growth trajectory. ProMach's commitment to the European packaging market is evident, with this facility expansion being the latest in a series of investments. Over the past three years, the company has also acquired several firms across Spain and Italy.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Eco-system Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of the Impact of Geopolitical Scenario on the Industry

- 4.5 Pricing Analysis

- 4.6 Import and Export Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increased Demand from Pharmaceutical and Chemical Industries

- 5.1.2 Innovations in Technology Driving the Demand for Automated Capping Machines

- 5.2 Market Restraints

- 5.2.1 Presence of Alternative Solutions and High Initial Investments

6 MARKET SEGMENTATION

- 6.1 By Technology

- 6.1.1 Automatic

- 6.1.2 Semi-automatic

- 6.2 By Cap Type

- 6.2.1 ROPP Caps

- 6.2.2 Screw Caps

- 6.2.3 Snap-on-Caps

- 6.2.4 Corks

- 6.3 By End User

- 6.3.1 Pharmaceuticals

- 6.3.2 Personal Care and Cosmetics

- 6.3.3 Food and Beverage

- 6.3.4 Chemicals

- 6.3.5 Automotive

- 6.3.6 Other End Users

- 6.4 By Geography

- 6.4.1 North America

- 6.4.1.1 United States

- 6.4.1.2 Canada

- 6.4.2 Europe

- 6.4.2.1 United Kingdom

- 6.4.2.2 Germany

- 6.4.2.3 France

- 6.4.3 Asia

- 6.4.3.1 China

- 6.4.3.2 India

- 6.4.3.3 Japan

- 6.4.4 Australia & New Zealand

- 6.4.5 Latin America

- 6.4.5.1 Mexico

- 6.4.5.2 Brazil

- 6.4.6 Middle East and Africa

- 6.4.6.1 United Arab Emirates

- 6.4.6.2 Saudi Arabia

- 6.4.6.3 South Africa

- 6.4.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 E-PAK Machinery Inc.

- 7.1.2 Accutek Packaging Equipment Companies Inc.

- 7.1.3 Barry-Wehmiller Group, Inc.

- 7.1.4 Phoenix Dison Tec LLC

- 7.1.5 Krones AG

- 7.1.6 LPE(Levapack)

- 7.1.7 Closure Systems International Inc (CSI)

- 7.1.8 Ronchi Mario S.p.A.

- 7.1.9 Likai Technology Co., Ltd.

- 7.1.10 ProMach Inc.

- 7.1.11 Marchesini Group S.p.A.